Air Pressure Test Troubleshooting

Identify leaks, ensure seals, and measure pressure precisely for optimal system performance and safety.

Understanding Air Pressure Tests

An Air Pressure Test is crucial for maintaining system integrity in various applications, from HVAC systems to industrial machinery. This test allows you to identify weaknesses within a system and determine if there are any air leaks that may compromise performance. When performing a pressure test, you essentially introduce a controlled amount of air into a system and monitor it for any pressure drops over a defined period.

Importance of a Proper Test Procedure

Having a well-defined test procedure is key to addressing any issues that might arise during the testing phase. In essence, a solid test procedure ensures that every step is documented and standardized. It helps the technician to maintain the consistency of results, addresses any potential component failures, and pinpoints seal failures that may occur during the test.

Dealing with Pressure Drops

A pressure drop is an immediate signal of trouble during an air pressure test. If you notice a significant drop in gauge readings within a short time, something is probably amiss. This could indicate an air leak or possibly a more serious issue, such as a seal failure or component failure. Understanding the signs allows for quicker troubleshooting and prevents more extensive damage down the line.

Gauge Readings: What They Mean

Monitoring your gauge readings is essential during the air pressure test. They serve as the first line of defense in detecting any discrepancies within the system. If your gauge readings start showing irregularities, take immediate corrective actions. Check every connection and valve, as these can often be the culprits behind unexpected pressure losses.

Common Causes of Air Leaks

Knowing common causes of air leaks can help save time during troubleshooting. These leaks can happen in various places, like connections, joints, and seals. In some cases, it may even stem from a defective or worn-out part within the system. Regular checks of components such as hoses and gaskets can reduce the probability of leaks occurring.

Seal Failure: What to Look For

Seal failure is a significant issue that can lead to air leaks and pressure drops. Pay close attention to the seals around valves and fittings during your inspection. Over time, seals can wear out or become brittle, causing them to fail. Identifying signs of seal degradation early on can save you a lot of hassle during your air pressure testing and maintain overall system integrity.

Component Failures and Their Implications

A component failure can stem from various reasons, including fatigue, manufacturing defects, or improper installation. Sometimes, a failed component won't give any noticeable signs until you perform an air pressure test. Therefore, it's crucial to regularly inspect and maintain all components within your system, ensuring they are operating effectively.

Effective Troubleshooting Techniques

When faced with an issue during an air pressure test, having a troubleshooting strategy becomes vital. Start by checking the obvious: loose connections, worn-out seals, and any visible damage. Then, consult your test procedure documentation for any additional tests or checks you can perform. This methodical approach can often reveal the root cause of the problem.

Leak Detection Methods

There are various methods for leak detection that can aid in identifying the source of an air leak. One common method involves the use of soap solution; applying it to joints and connections during the pressure test can reveal bubbling where air escapes. Other methods include ultrasonic leak detection, which uses sound waves to identify leaks. Each method has its advantages, and depending on your setup, you may find one more effective than the other.

The Role of Air Compressors in Testing

An air compressor is often required to introduce the air pressure during the test. It's essential to use a reliable compressor that provides consistent and adequate pressure to your system. Failure to do so may affect the test results, leading to inaccurate gauge readings. Always check your compressor's settings and functionality prior to beginning your air pressure test.

Documenting Your Findings

After a test, it’s essential to document your findings meticulously. Take note of pressure readings, durations, and any observations made during the test. This data will be beneficial not just for resolving current issues but also for future references and planning maintenance schedules. Proper documentation enhances overall system integrity and promotes quality assurance.

Safety Considerations

Safety should never be taken lightly when conducting an air pressure test. For effective testing while minimizing risks, refer to these safety tips before proceeding with your testing. Proper protective gear and following necessary safety protocols will ensure that you can conduct your tests without the threat of injury.

Final Thoughts on Air Pressure Testing

Successfully troubleshooting air pressure tests hinges on understanding the process and knowing what to look for in terms of seal failures, air leaks, and component failures. The effectiveness of your test procedure greatly improves with practice, allowing you to maintain your system's integrity over time. For more details on the essentials of pressure testing, check out resources like this article.

Further Reading

To deepen your understanding of air pressure testing, you may want to explore additional articles like this comprehensive guide on Air Pressure Testing. The more equipped you are with knowledge and techniques, the better your outcomes will be during air pressure tests and general system maintenance.

Conclusion

In wrapping up, air pressure testing serves as an essential maintenance tool that ensures the longevity of any system that utilizes compressed air. By being aware of the common issues and effective troubleshooting techniques, you can carry out the test more effectively. Don’t forget—documentation, maintenance, and safety protocols are just as important as understanding the technical details of your air pressure test!

Posts Relacionados

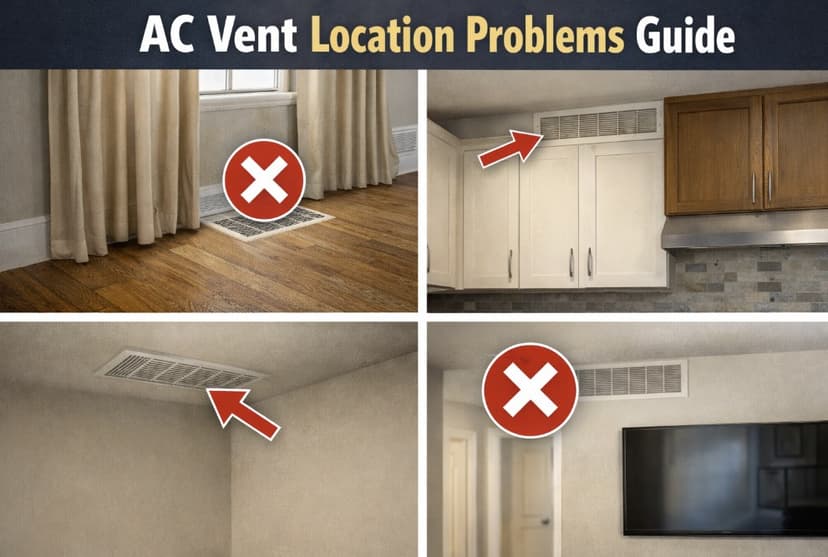

Ac Vent Location Problems Guide

Improper placement causes uneven temperatures, poor airflow, and reduced energy efficiency. Identify these issues for optimal comfort.

Air Return Placement Common Mistakes And Tips

Improper placement causes poor airflow, energy waste, and discomfort; avoid these mistakes for optimal HVAC performance.

Choosing The Right Smart Security Overview

Selecting the best smart security system means evaluating features, assessing needs, and ensuring reliable home protection.